Search for products

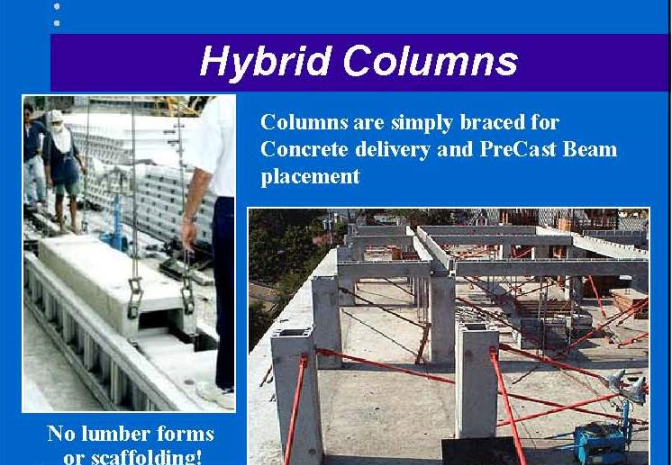

Hybrid Precast Concrete Column and Beam Construction

Brief Description

The WAFFLE-CRETE Hybrid Building System replaces traditional column and beam forming material with precast forms that become a part of the structure. The forms have precise dimensions and a smooth, clean surface. Bracing and shoring is greatly reduced and grinding and patching is kept to a minimum. Erection is faster, requires less labor, and the work site is cleaner and safer, giving the contractor increased job site and project control.

Request More Information Sign Up for Product AlertsProduct Details

The WAFFLE-CRETE Hybrid Building System replaces traditional column and beam forming material with precast forms that become a part of the structure. The forms have precise dimensions and a smooth, clean surface. Bracing and shoring is greatly reduced and grinding and patching is kept to a minimum. Erection is faster, requires less labor, and the work site is cleaner and safer, giving the contractor increased job site and project control.

Product Selling Benefits

Molds are made of durable plastic and aluminum and are easy to clean, set, cast and strip. One adjustable mold casts both column and beam forming elements. Insulation in the mold body assures overnight curing without additional steam or electric heat. Aluminum side rails flex open allowing the precast element to be easily removed from the mold.

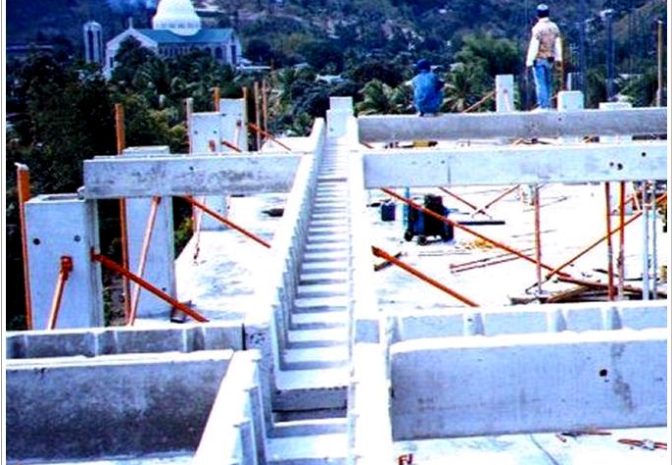

Precast forming elements are erected as column and beam forms become an integral part of the structure. Reinforced U-shaped column elements are erected on poured concrete pads and secured one to another with a preformed bolted connection. Beam elements are set on the columns forming the floor grid. Precast floor panels are set on the beams and secured with a bolted connection. Plumbing and electrical conduit is placed in and through the beam elements. Column and beam reinforcing is put in place and the columns and beams are poured.

Ridges built into the forms create shear keys in the precast elements. These shear keys lock the precast elements and poured-in-place concrete together. The poured concrete ties the column and beam forming elements to the floor panels, and the grid becomes one monolithic structural unit.

Ridges built into the forms create shear keys in the precast elements. These shear keys lock the precast elements and poured-in-place concrete together. The poured concrete ties the column and beam forming elements to the floor panels, and the grid becomes one monolithic structural unit.

Products Specs

| Seller Objective: | Open to discussing any type of sales arrangement |

| Patent / IP Status: | Utility patent issued |

| Inventory in Stock: | In stock and available for sale |

| Number of Units in Stock: | < 100 |

| Suggested Retail Price: | N/A |

| Wholesale Price: | N/A |

| Estimated Cost/Unit: | N/A |

| Minimum Order/Units: | N/A |

| Prior Sales Activity: | Large Projects in Philippines, Indonesia, Guam, Micronesia, USA, Venezuela, etc. Call or email to discuss. |

Print Page